Accelerate certification with TÜV-certified tools

Leverage pre-certified toolchains to reduce additional safety validation efforts, helping developers achieve compliance faster while lowering certification costs and complexity.

Solution

Leverage pre-certified toolchains to reduce additional safety validation efforts, helping developers achieve compliance faster while lowering certification costs and complexity.

Ensure system reliability and prevent critical failures with comprehensive validation, static and dynamic code analysis, and automated workflows that reduce risk in functional safety applications.

Out-of-the-box compliance solutions simplify certification processes, reducing development effort while ensuring adherence to automotive, industrial automation, and medical device safety standards.

Functional safety in automotive, industrial automation, and medical devices requires strict validation and adherence to industry standards. Achieving compliance can be complex, time-consuming, and costly, but IAR’s TÜV-certified tools streamline the process, reducing the need for costly redesigns and extensive validation efforts. With pre-certified compilers and analysis tools, teams can build safety-critical applications with confidence while ensuring software reliability and minimizing certification complexity.

Meeting certification standards like ISO 26262, IEC 61508, and IEC 62304 can take up to 12 months and require significant resources if validating tools independently. Using TÜV-certified development tools eliminates the need for additional qualification steps, reducing liability risks, firmware updates, and regulatory setbacks.

IAR offers TÜV-certified tools covering 10 different safety standards, along with long-term support, prioritized assistance, and rapid issue resolution through a dedicated Functional Safety Support Agreement. IAR’s static and dynamic safety analysis continuously verifies software integrity, detecting vulnerabilities before deployment and minimizing system failures. Automated validation workflows ensure every software update meets safety requirements, reducing risk and lowering development costs.

With pre-certified tools and expert support, IAR enables development teams to focus on certifying their applications rather than their tools, accelerating compliance and reducing overall certification effort.

Building blocks

Ensure safety-critical reliability with advanced verification and compliance-ready development tools.

Product

Complete toolchain with an industry-leading compiler, debugger, and analysis tools, ensuring efficient, high-performance embedded development.

Product

Automates builds and testing in CI/CD pipelines with high-performance command-line tools, enabling scalable cloud and on-prem workflows.

Product

Detects defects, security vulnerabilities, and compliance issues early with powerful static analysis for MISRA C/C++, CERT C/C++, and industry standards

Product

Identifies runtime errors, memory leaks, and overflows, improving software reliability and debugging efficiency.

Product

Enables graphical state machine modeling for efficient system design, automated code generation, and validation of complex embedded applications.

Pre-validated toolchains eliminate the need for additional qualification, enabling faster compliance and reducing certification complexity. IAR’s certified tools cover 10 safety standards, including IEC 61508, ISO 26262, EN 50128, EN 50657, IEC 62304, ISO 25119, ISO 13849, IEC 62061, IEC 61511, and IEC 60730.

Continuous verification detects vulnerabilities early, preventing software failures and ensuring system integrity.

Streamlines compliance for software updates, reducing certification efforts, mitigating risks, and lowering overall development costs.

|

Industrial IEC 61508 |

Automotive ISO 26262 |

Railway EN 50128 EN 50657 |

Medical IEC 62304 |

Agriculture & forestry ISO 25119 |

Machinery control ISO 13849 IEC 62061 |

Process industry IEC 61511 |

Household appliances IEC 60730 |

|

|

Arm |

||||||||

| RISC-V | ||||||||

| Renesas RL78 | ||||||||

| Renesas RX | ||||||||

| Renesas RH850 | ||||||||

| STM8 |

Customer stories

Read caseQuality and certification are critical for the future of high-tech medical devices. By using C-STAT, we can improve code quality while preparing for IEC 62304-certified functional safety upgrades to meet regulatory standards.

Read caseWe were required to migrate MCU platforms from a legacy architecture to an Arm architecture with integrated security features, in addition to meeting AUTOSAR standard specifications, within only six months lead time. In order to meet the project schedule, we got direct and flexible support from IAR.

Read caseThe biggest surprise was that it was so simple. The cost for just the bootloader made sense. Then, we get all this other stuff on top of it that lets us do all kinds of really cool security stuff. I mean, then it just became kind of a no-brainer.

TÜV SÜD-certified toolchains simplify certification by providing pre-validated tools that reduce the need for additional safety validation.

Pre-certified toolchains accelerate compliance by eliminating the need for extensive in-house validation and reducing certification costs.

Meeting functional safety standards strengthens market access, enhances brand credibility, and ensures regulatory approval.

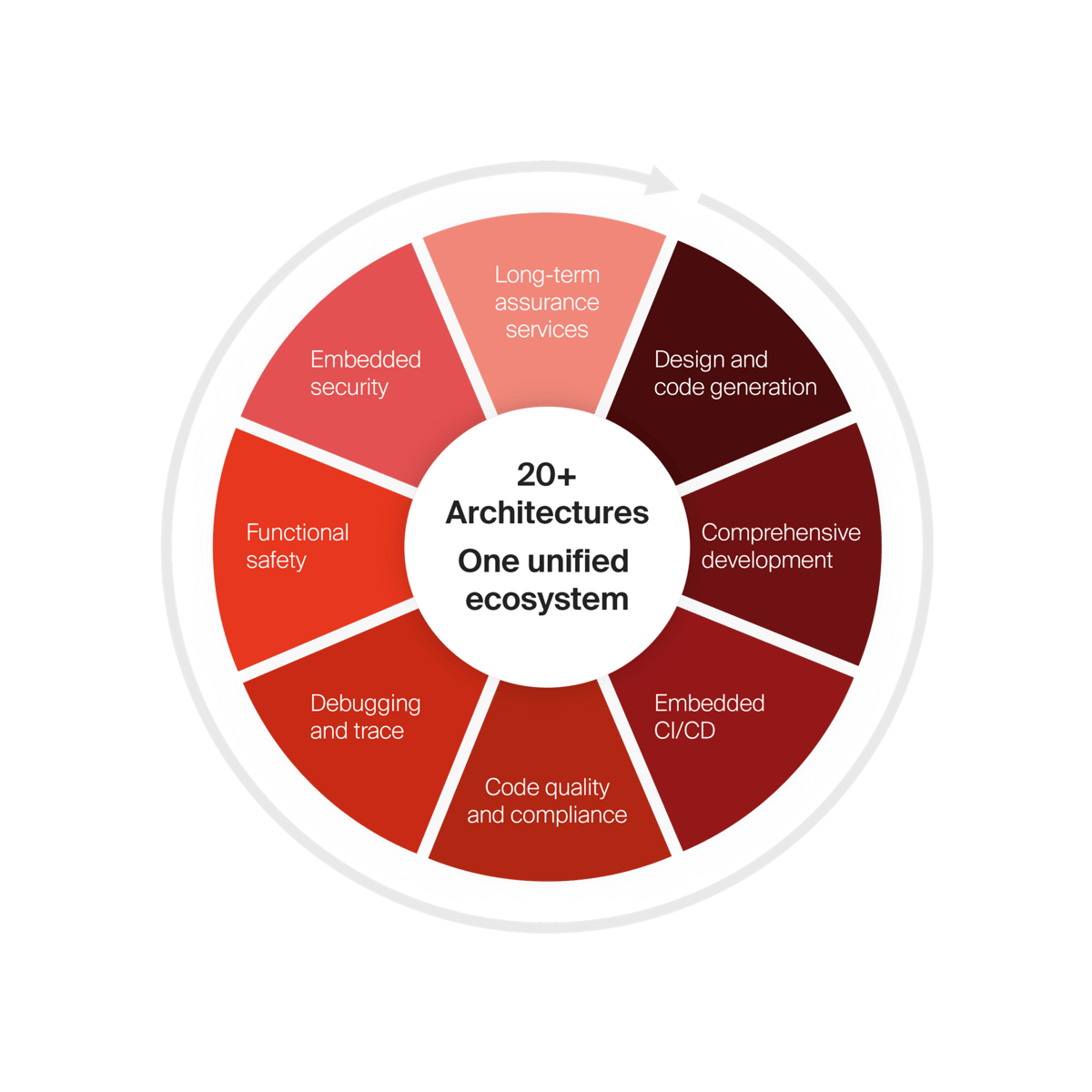

IAR embedded development platform

Scale development operations with freedom and flexibility, accelerate innovation with code confidence and simplify compliance while strengthening security.

With our platform, you get access to everything.